Working principles of SLA (Stereolithography)

SLA 3D printing uses a process where liquid photopolymer resin is cured into solid form using a UV laser. The process involves the following steps:

- Preparation: A vat of liquid resin is placed in a printer, with a build platform submerged in the resin.

- Laser Curing: A UV laser traces the first layer of the model on the resin surface, solidifying the resin where the laser touches.

- Layer by Layer: After the first layer is complete, the build platform lowers slightly, and the printer adds a new layer of resin. The laser then cures this layer, bonding it to the previous one.

- Post-Processing: Once printing is complete, the model is removed from the resin vat and often requires additional curing under UV light to achieve maximum strength.

How's the SLS (Selective Laser Sintering) working?

SLS involves the use of a laser to sinter powdered materials, typically nylon, into solid structures. The process includes:

- Layering Powder: A thin layer of nylon powder is spread across the build platform.

- Laser Sintering: A high-powered laser scans the surface, fusing the powder particles together according to the design. The laser’s heat causes the powder to melt and solidify, forming a solid layer.

- Layer Addition: Once a layer is complete, the build platform lowers, and a new layer of powder is spread over the previous one. The laser then sinters this new layer.

- Cooling and Removal: After printing, the part is allowed to cool within the powder bed, which supports the structure during cooling. Once cooled, the excess powder is removed, revealing the final part.

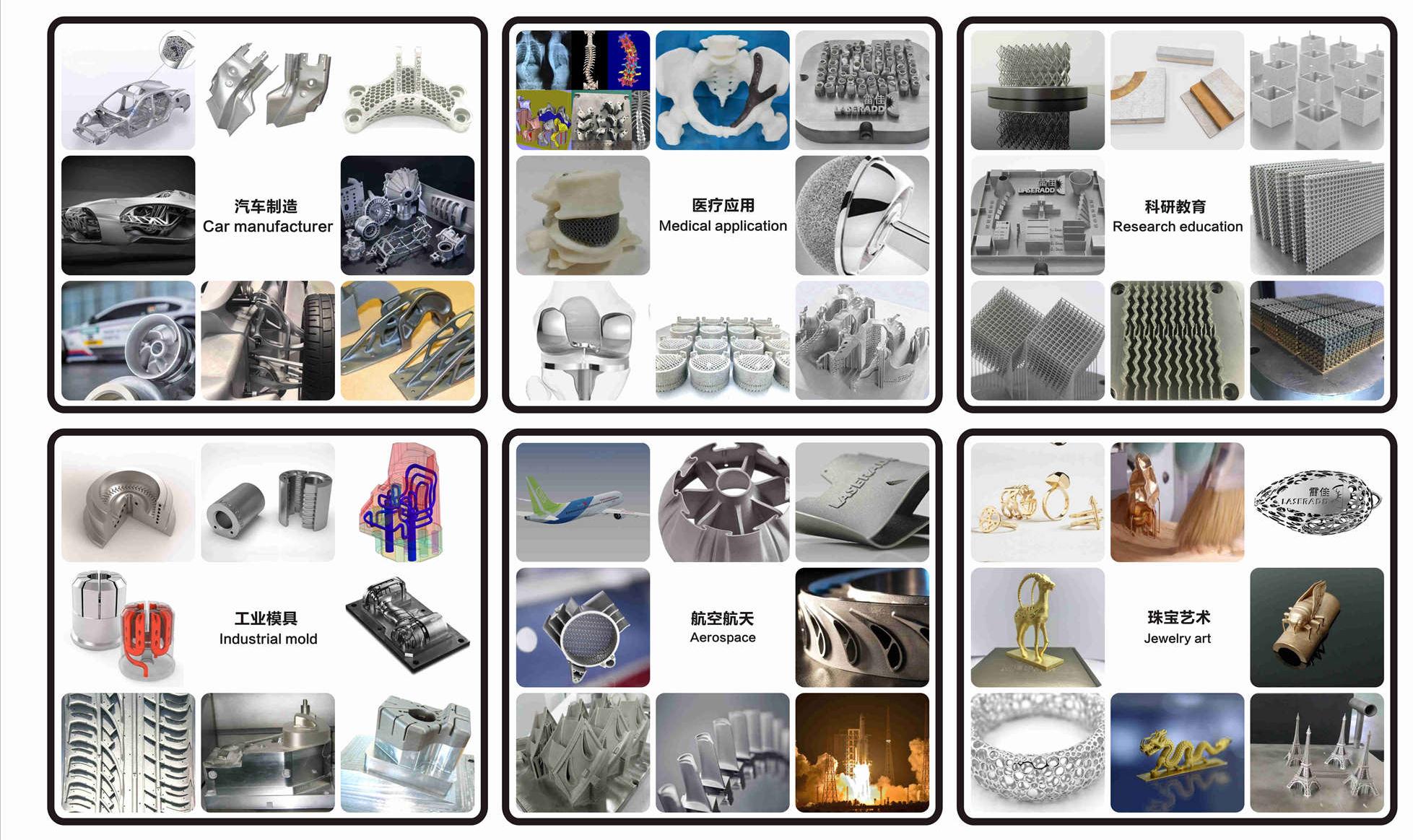

3D printing services have a wide range of applications

Medical Devices,Aerospace,Automotive Parts,Prototyping, Manufacturing,Tooling,End-Use Parts,Education and Research,Architecture and Construction,Art and Design etc.