Luxciry: Revolutionizing the Automotive and Aerospace Industries with 3D Printing

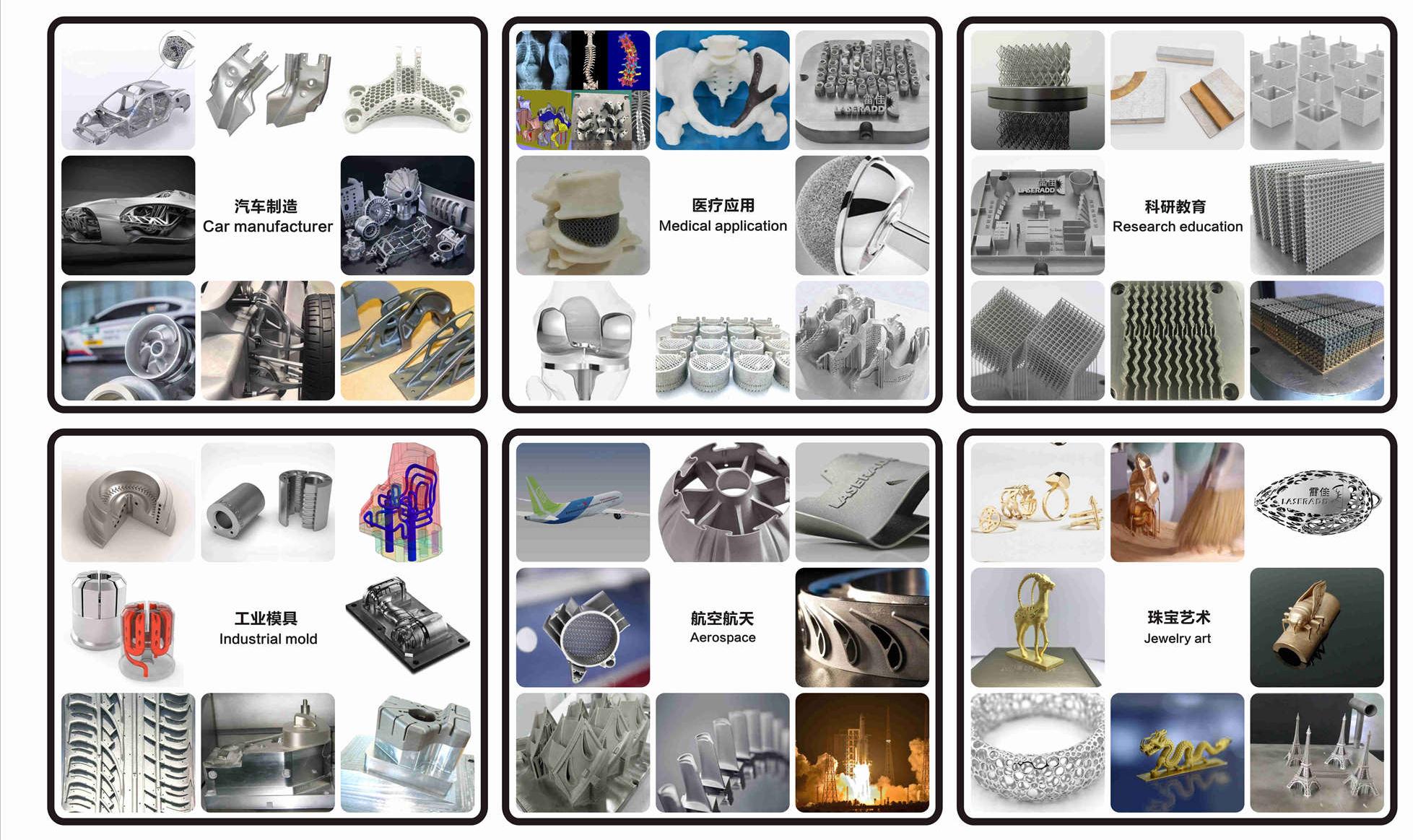

In the modern era, where technological advancements are rapidly transforming industries, the role of 3D printing has become increasingly significant. Luxciry, a leading 3D printing manufacturer, is at the forefront of this revolution, particularly in the automotive and aerospace sectors. This article delves into how Luxciry is leveraging 3D printing technology to innovate and enhance these industries, offering unprecedented advantages in terms of design, efficiency, and sustainability.

The Rise of 3D Printing in Automotive and Aerospace

The automotive and aerospace industries are inherently complex, requiring precision engineering, high-quality materials, and innovative design solutions. Traditionally, these industries have relied on conventional manufacturing techniques that often involve significant time, cost, and resource investments. However, the advent of 3D printing has introduced a paradigm shift, enabling manufacturers to overcome these challenges.

3D printing, also known as additive manufacturing, allows for the creation of three-dimensional objects from a digital file. This technology builds objects layer by layer, offering unparalleled flexibility and customization. Luxciry has harnessed this capability to produce intricate components that meet the stringent standards of automotive and aerospace applications.

Luxciry’s Impact on the Automotive Industry

In the automotive sector, Luxciry’s 3D printing services are transforming how vehicles are designed, prototyped, and manufactured. The ability to produce complex geometries that are difficult or impossible to achieve with traditional methods is one of the key benefits Luxciry offers. This capability allows for the optimization of parts, leading to lighter vehicles with improved fuel efficiency.

Moreover, Luxciry’s 3D printing technology significantly reduces the time required for prototyping. Designers and engineers can quickly iterate and test multiple designs, accelerating the development process. This rapid prototyping capability not only saves time but also reduces costs, making innovation more accessible.

Another critical advantage is the customization potential. Luxciry enables automotive manufacturers to produce bespoke parts tailored to specific customer requirements. This level of customization enhances the driving experience and allows for greater personalization of vehicles.

Case Study: Luxciry’s Collaboration with a Leading Car Manufacturer

Recently, Luxciry partnered with a renowned car manufacturer to design and produce lightweight, high-strength components for a new electric vehicle model. By utilizing advanced 3D printing techniques, Luxciry was able to reduce the weight of certain parts by up to 30%, contributing to the vehicle’s overall efficiency and performance.

Advancements in Aerospace Through Luxciry’s 3D Printing

The aerospace industry stands to gain immensely from Luxciry’s 3D printing capabilities. The production of aerospace components often involves complex geometries and the use of high-performance materials. Luxciry’s expertise in additive manufacturing addresses these challenges, offering a streamlined production process with enhanced material properties.

One of the most significant benefits in aerospace is weight reduction. Luxciry’s 3D printed components are not only lighter but also maintain the necessary strength and durability. This weight reduction is critical in aerospace, where every kilogram saved can lead to substantial fuel savings and increased payload capacity.

Furthermore, Luxciry’s 3D printing technology enables the consolidation of multiple parts into a single component. This consolidation reduces the number of assembly operations and potential points of failure, enhancing the reliability and performance of aerospace systems.

Innovative Materials and Processes

Luxciry is at the cutting edge of material innovation, utilizing advanced composites and metal alloys specifically designed for aerospace applications. These materials offer superior thermal and mechanical properties, ensuring that 3D printed components can withstand the harsh conditions of aerospace environments.

In addition to material advancements, Luxciry employs state-of-the-art 3D printing processes, such as Selective Laser Sintering (SLS) and Direct Metal Laser Sintering (DMLS), to produce high-quality components with exceptional precision and detail.

Sustainability and Efficiency: The Luxciry Advantage

One of the most compelling aspects of Luxciry’s 3D printing services is their contribution to sustainability. Traditional manufacturing processes often result in significant material waste, as excess material is removed to create the final shape. In contrast, 3D printing is an additive process, using only the material necessary to build the part, thus minimizing waste.

This reduction in waste is particularly beneficial in industries like automotive and aerospace, where high-performance materials can be costly and resource-intensive. By optimizing material usage, Luxciry not only reduces costs but also lessens the environmental impact of production.

Additionally, the localized nature of 3D printing allows for on-demand production, reducing the need for large inventories and the associated storage and transportation costs. This on-demand capability also supports a more agile supply chain, enabling manufacturers to respond quickly to changes in demand and market conditions.

Future Prospects and Innovations

As 3D printing technology continues to evolve, Luxciry is committed to staying at the forefront of innovation. The company is investing in research and development to explore new materials, improve printing techniques, and expand the range of applications for 3D printing in automotive and aerospace industries.

One area of focus is the integration of smart technologies into 3D printed components. By embedding sensors and other electronic elements during the printing process, Luxciry aims to create intelligent parts that can monitor their own performance and communicate with other systems, paving the way for smarter, more connected vehicles and aircraft.

Another promising development is the potential for 3D printing to support the production of spare parts and maintenance components. Luxciry is exploring the feasibility of creating digital inventories, where parts can be printed on demand, reducing the need for physical storage and ensuring that replacement parts are always available when needed.

Conclusion

Luxciry’s pioneering efforts in 3D printing are reshaping the automotive and aerospace industries, offering new possibilities for design, efficiency, and sustainability. By embracing this transformative technology, Luxciry is not only enhancing the capabilities of these sectors but also contributing to a more sustainable and innovative future.

As the journey of 3D printing continues, Luxciry remains dedicated to pushing the boundaries of what is possible, driving progress and setting new standards in manufacturing excellence. With a commitment to quality, innovation, and customer satisfaction, Luxciry is poised to lead the next wave of advancements in automotive and aerospace technology.