In today’s rapidly evolving industrial landscape, the demand for precision and efficiency in manufacturing has never been higher. Luxciry, a leading name in the realm of CNC machining and 3D printing, stands at the forefront of this transformation, offering state-of-the-art solutions for complex mechanical systems. This article delves into the intricacies of Luxciry’s CNC machining services, highlighting their innovative approach and the benefits they bring to various industries.

Understanding CNC Machining

CNC (Computer Numerical Control) machining is a manufacturing process that employs computerized controls and machine tools to remove layers of material from a workpiece. This process is instrumental in creating precision parts and components for complex mechanical systems. Luxciry leverages cutting-edge CNC technology to deliver unparalleled accuracy and efficiency in manufacturing.

The Role of CNC Machining in Modern Manufacturing

In modern manufacturing, CNC machining plays a pivotal role in ensuring products meet exact specifications. Luxciry’s CNC machining services are designed to cater to industries that demand high precision, such as aerospace, automotive, and medical devices. By utilizing advanced software and machinery, Luxciry is able to produce intricate parts with minimal tolerances, ensuring optimal performance and reliability.

Luxciry’s CNC Machining Capabilities

Luxciry prides itself on its comprehensive CNC machining capabilities, which include milling, turning, and multi-axis machining. These capabilities enable the production of complex geometries and intricate designs that would be challenging to achieve with traditional manufacturing methods.

Milling

Milling is a machining process that involves the use of rotary cutters to remove material from a workpiece. Luxciry’s milling services are equipped with the latest technology, allowing for high-speed and high-precision operations. This ensures that even the most complex designs are executed with precision and accuracy.

Turning

Turning is a machining process where a cutting tool moves linearly while the workpiece rotates. Luxciry’s turning services are ideal for creating cylindrical parts with tight tolerances. The company’s advanced turning machines are capable of handling a wide range of materials, from metals to plastics, making them versatile for various applications.

Multi-Axis Machining

Multi-axis machining involves the use of CNC machines that can move along multiple axes simultaneously. This capability allows Luxciry to produce parts with complex geometries that would be impossible to achieve with traditional 3-axis machines. The company’s multi-axis machining services are particularly beneficial for industries that require intricate and precise components.

3D Printing: Complementing CNC Machining

In addition to CNC machining, Luxciry also specializes in 3D printing, a revolutionary technology that complements traditional machining methods. 3D printing enables the creation of complex shapes and structures that are difficult or impossible to achieve with conventional techniques. By integrating 3D printing with CNC machining, Luxciry offers a hybrid approach that maximizes design flexibility and manufacturing efficiency.

The Advantages of 3D Printing

3D printing offers several advantages over traditional manufacturing methods. It allows for rapid prototyping, enabling designers to quickly iterate and refine their designs. Additionally, 3D printing reduces material waste, as it builds parts layer by layer, using only the necessary amount of material. Luxciry’s 3D printing services are tailored to meet the needs of industries that demand high precision and customization.

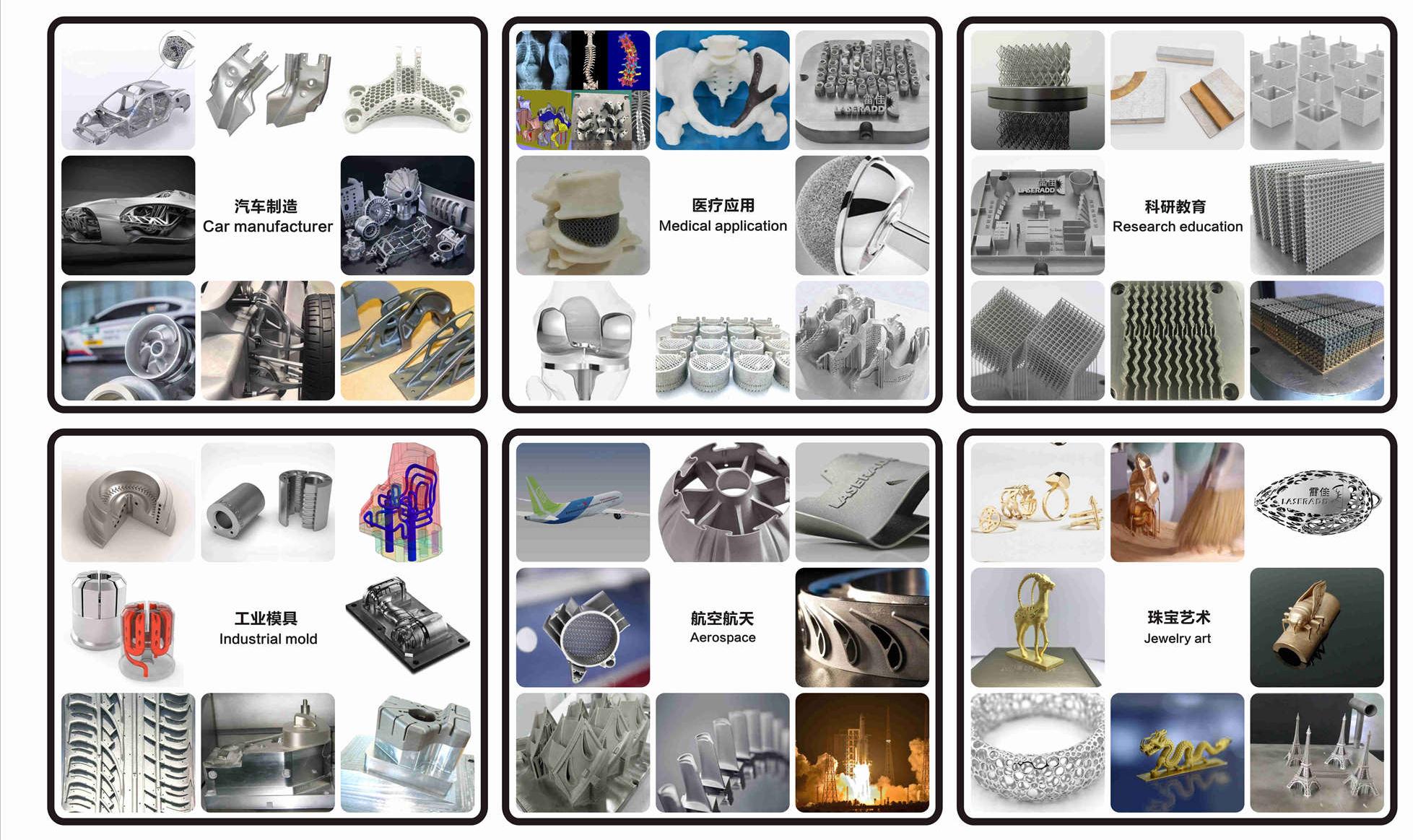

Applications of Luxciry’s CNC Machining and 3D Printing Services

Luxciry’s CNC machining and 3D printing services find applications in a wide range of industries. From aerospace to medical devices, Luxciry’s expertise in precision manufacturing is trusted by companies around the world. The following sections explore some of the key industries that benefit from Luxciry’s services.

Aerospace

The aerospace industry demands high precision and reliability in its components. Luxciry’s CNC machining services are ideal for producing critical aerospace parts, such as turbine blades and structural components. The company’s advanced machinery ensures that these parts meet the stringent quality standards required by the aerospace industry.

Automotive

In the automotive industry, Luxciry’s CNC machining and 3D printing services are used to produce engine components, transmission parts, and custom prototypes. The company’s ability to deliver high-precision parts with quick turnaround times makes it a preferred partner for automotive manufacturers.

Medical Devices

Medical devices require exceptional precision and quality to ensure patient safety and efficacy. Luxciry’s CNC machining services are employed to manufacture surgical instruments, implants, and other medical components. The company’s commitment to quality and precision makes it a trusted supplier for the medical device industry.

Quality Assurance at Luxciry

Quality assurance is a cornerstone of Luxciry’s operations. The company employs rigorous quality control measures to ensure that every part and component meets the highest standards of precision and accuracy. Luxciry’s quality assurance process includes thorough inspections, testing, and validation to guarantee the reliability and performance of its products.

Inspection and Testing

Luxciry utilizes advanced inspection and testing equipment to verify the quality of its products. This includes coordinate measuring machines (CMMs), optical scanners, and other precision instruments. These tools enable Luxciry to conduct detailed inspections and ensure that every part meets the specified tolerances and dimensions.

Continuous Improvement

Luxciry is committed to continuous improvement in its manufacturing processes. The company invests in the latest technology and training to enhance its capabilities and maintain its competitive edge. By fostering a culture of innovation and excellence, Luxciry ensures that its customers receive the highest quality products and services.

Conclusion

Luxciry’s CNC machining and 3D printing services are at the cutting edge of precision manufacturing. By combining advanced technology with a commitment to quality, Luxciry delivers solutions that meet the demands of complex mechanical systems across various industries. Whether it’s aerospace, automotive, or medical devices, Luxciry’s expertise and innovation make it a trusted partner for companies seeking precision and efficiency in their manufacturing processes.

As the industrial landscape continues to evolve, Luxciry remains dedicated to pushing the boundaries of what’s possible in CNC machining and 3D printing. With a focus on quality, innovation, and customer satisfaction, Luxciry is poised to lead the way in the future of precision manufacturing.