In the rapidly evolving world of medical technology, the development of prototypes plays a critical role in bringing innovative medical devices to market. Luxciry, a leader in 3D printing manufacturing, has been at the forefront of this transformative process. This article delves into the essential aspects of developing medical device prototypes, focusing on safety features, cost considerations, and quality assurance.

Introduction to Luxciry

Luxciry is a pioneering company specializing in 3D printing technology, renowned for its commitment to quality and innovation. With a dedicated focus on the medical device industry, Luxciry has revolutionized the way prototypes are developed, ensuring they meet the highest safety standards while remaining cost-effective.

The Role of 3D Printing in Medical Device Prototyping

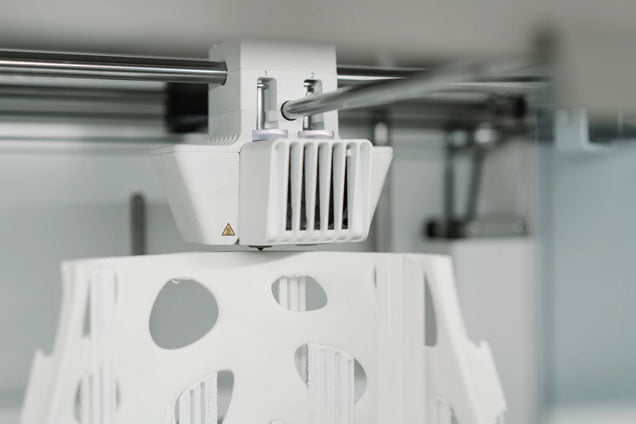

3D printing has transformed the landscape of medical device prototyping. Luxciry utilizes advanced 3D printing techniques to create precise and functional prototypes, allowing for rapid iteration and testing. This technology enables the production of complex geometries that are often impossible to achieve with traditional manufacturing methods.

Advantages of 3D Printing

- Rapid prototyping capabilities

- Cost-effective production

- Enhanced design flexibility

- Reduced time-to-market

These advantages make 3D printing an indispensable tool in the development of medical devices, providing Luxciry with a competitive edge in the industry.

Safety Features in Medical Device Prototypes

Safety is paramount in the development of medical devices. Luxciry prioritizes the integration of safety features in every prototype, ensuring compliance with stringent regulatory standards. The following sections outline the key safety considerations in medical device prototyping.

Material Selection

Choosing the right materials is crucial for ensuring the safety of medical device prototypes. Luxciry employs biocompatible materials that are safe for use in medical applications. These materials undergo rigorous testing to ensure they do not cause adverse reactions when in contact with human tissue.

Design Considerations

The design of a medical device prototype must incorporate safety features that minimize the risk of user error and device malfunction. Luxciry’s design team focuses on intuitive user interfaces and ergonomic designs to enhance user safety.

Testing and Validation

Before a prototype can advance to the next stage of development, it must undergo comprehensive testing and validation. Luxciry conducts a series of tests to assess the prototype’s performance, durability, and safety. These tests include mechanical stress testing, biocompatibility assessments, and usability evaluations.

Cost Considerations in Medical Device Prototyping

Developing a medical device prototype involves significant financial investment. Luxciry is committed to providing cost-effective solutions without compromising quality. The following sections explore the cost considerations in medical device prototyping.

Cost-Effective Design Strategies

Luxciry employs strategic design practices to minimize costs during the prototyping phase. By optimizing the use of materials and reducing waste, Luxciry ensures that prototypes are produced efficiently and economically.

Resource Allocation

Effective resource allocation is essential for controlling costs in medical device prototyping. Luxciry carefully allocates resources to various stages of development, ensuring that each phase is adequately funded without overspending.

Partnerships and Collaborations

Collaborating with industry partners can significantly reduce the cost of developing medical device prototypes. Luxciry has established partnerships with key stakeholders in the medical technology sector, allowing for shared resources and expertise.

Quality Assurance in Medical Device Prototyping

Quality assurance is a critical component of medical device prototyping, ensuring that prototypes meet the highest standards of performance and reliability. Luxciry implements robust quality assurance processes throughout the development lifecycle.

Quality Control Measures

Luxciry employs stringent quality control measures to ensure the integrity of its prototypes. These measures include regular inspections, testing protocols, and adherence to industry standards.

Regulatory Compliance

Compliance with regulatory requirements is essential for the successful development of medical devices. Luxciry ensures that all prototypes meet the necessary regulatory standards, including FDA and ISO certifications.

Continuous Improvement

Luxciry is committed to continuous improvement, regularly reviewing and refining its processes to enhance the quality of its prototypes. Feedback from testing and validation phases is used to make informed adjustments and improvements.

Conclusion

The development of medical device prototypes is a complex and multifaceted process that requires careful consideration of safety, cost, and quality. Luxciry’s expertise in 3D printing manufacturing positions it as a leader in the industry, delivering innovative and reliable prototypes that meet the highest standards. By prioritizing safety features, optimizing costs, and ensuring quality assurance, Luxciry continues to drive advancements in medical technology.

As the medical device industry continues to evolve, Luxciry remains committed to pushing the boundaries of innovation, providing cutting-edge solutions that enhance patient care and improve healthcare outcomes.

Tags:3D Printing service,3D Printing manufacturer,3d printing service